Humidity control is an essential aspect of maintaining a comfortable and healthy environment. It plays a critical role in various industries, including electronics, pharmaceuticals, food and beverage, and more. At the heart of humidity control is the humidity indicator, a device that provides a visual representation of the humidity level in a given environment. This article will delve into the intricacies of humidity indicators and their role in humidity control.

Understanding the concept of humidity is crucial to grasping the importance of humidity indicators. Humidity refers to the amount of water vapor present in the air. It is usually expressed as a percentage, indicating the proportion of maximum moisture the air could potentially hold at a given temperature. High humidity can lead to mold growth and discomfort, while low humidity can cause dry skin and respiratory issues. Hence, maintaining an optimal humidity level is crucial, and this is where humidity indicators come into play.

Working Principle of Humidity Indicators

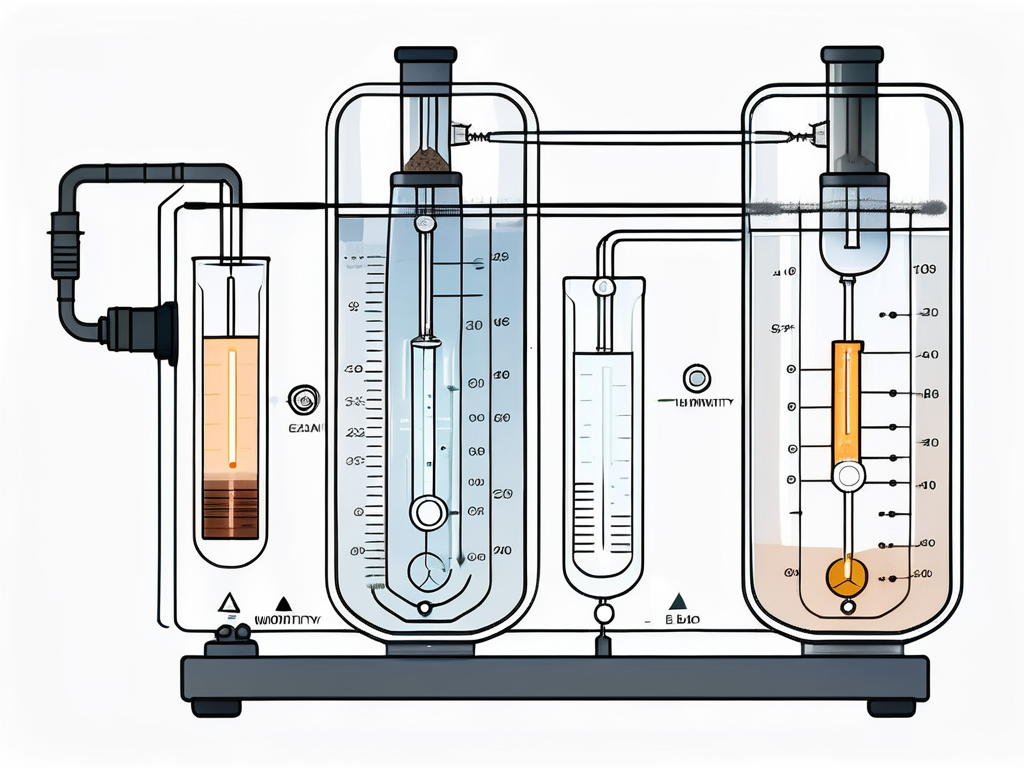

The working principle of humidity indicators is based on the hygroscopic property of certain materials. Hygroscopic materials have the ability to absorb and retain moisture from the environment. When these materials come into contact with air, they absorb or release moisture depending on the humidity level. This change in moisture content causes a physical change in the material, which can be measured and used to indicate the humidity level.

Most humidity indicators use a hygroscopic salt solution that changes color when it absorbs or releases moisture. The color change is usually from blue (dry) to pink (wet), providing a visual indication of the humidity level. This color change is reversible, meaning the indicator can be used multiple times.

Types of Humidity Indicators

There are several types of humidity indicators, each with its own advantages and disadvantages. The most common types include mechanical, electrical, and chemical indicators.

Mechanical humidity indicators work on the principle of hair tension. They use a human or animal hair that lengthens or shortens based on the humidity level. These indicators are simple and inexpensive, but they are not very accurate.

Role of Humidity Indicators in Humidity Control

Humidity indicators play a crucial role in humidity control. They provide a visual indication of the humidity level, allowing for timely adjustments to be made. This is particularly important in industries where humidity levels can affect product quality or cause damage to equipment.

For example, in the electronics industry, high humidity can lead to condensation, which can cause short circuits and damage electronic components. By using a humidity indicator, manufacturers can monitor the humidity level and take necessary steps to maintain it within the acceptable range.

Humidity Control Methods

There are several methods of controlling humidity, including ventilation, dehumidification, and humidification. The choice of method depends on the specific requirements of the environment and the level of control required.

Ventilation is the simplest method of controlling humidity. It involves exchanging the indoor air with outdoor air, either through natural or mechanical means. However, this method is not very effective in areas with high outdoor humidity or in sealed environments, such as laboratories or manufacturing facilities.

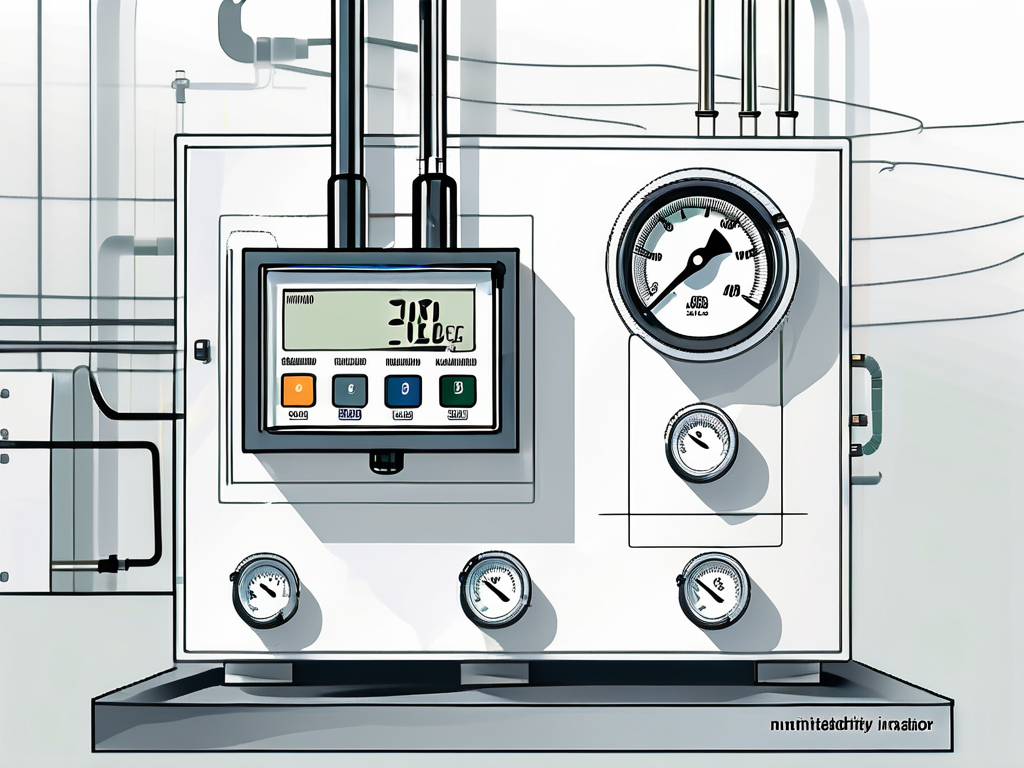

Dehumidification

Dehumidification is the process of removing moisture from the air. This is usually done using a dehumidifier, a device that cools the air to condense the moisture and then reheats it to a comfortable temperature. Dehumidifiers are effective in reducing humidity, but they can be expensive to run and maintain.

Another method of dehumidification is the use of desiccants. Desiccants are substances that absorb moisture from the air. They are often used in conjunction with humidity indicators to provide a visual indication of when the desiccant needs to be replaced.

Humidification

Humidification is the process of adding moisture to the air. This is usually done using a humidifier, a device that releases water vapor into the air. Humidifiers are effective in increasing humidity, but they can lead to over-humidification if not properly controlled.

Another method of humidification is the use of evaporative coolers. These devices work by evaporating water into the air, which increases the humidity and cools the air. Evaporative coolers are energy-efficient and can be used in dry climates, but they are not suitable for areas with high humidity.

Humidity Control in Different Industries

Humidity control is crucial in various industries, each with its own specific requirements. In the electronics industry, for example, humidity control is essential to prevent condensation, which can cause short circuits and damage electronic components. In the pharmaceutical industry, humidity control is necessary to maintain the efficacy of drugs and prevent microbial growth.

In the food and beverage industry, humidity control is important to prevent spoilage and maintain product quality. In the textile industry, humidity control is needed to prevent shrinkage and maintain the quality of the fabric. In the construction industry, humidity control is necessary to prevent mold growth and structural damage.

Humidity Control in the Electronics Industry

In the electronics industry, humidity control is crucial. High humidity can lead to condensation, which can cause short circuits and damage electronic components. Therefore, it is important to maintain a low humidity level in the production and storage areas.

Humidity indicators are often used in conjunction with desiccants in sealed packaging to protect sensitive electronic components during storage and transportation. The humidity indicator provides a visual indication of the humidity level inside the package, allowing for timely intervention if necessary.

Humidity Control in the Pharmaceutical Industry

In the pharmaceutical industry, humidity control is essential. High humidity can affect the efficacy of drugs and promote microbial growth. Therefore, it is important to maintain a controlled humidity level in the production, storage, and distribution areas.

Humidity indicators are often used in pharmaceutical packaging to monitor the humidity level during storage and transportation. They provide a visual indication of the humidity level, allowing for timely intervention if necessary. In addition, humidity control systems are often used in production areas to maintain a controlled environment.

Conclusion

Humidity control is an essential aspect of maintaining a comfortable and healthy environment. It plays a critical role in various industries, ensuring product quality and preventing damage to equipment. At the heart of humidity control is the humidity indicator, a simple yet effective tool for monitoring humidity levels.

Understanding the working principle and applications of humidity indicators is crucial for anyone involved in industries where humidity control is important. With the right knowledge and tools, maintaining an optimal humidity level can be a straightforward and effective process.